In General terms Impurity is referred as something, which is not pure. Some substance / component that may affect the SISPQ (Safety, Identity, Strength, Purity and Quality) of a drug substance/drug products (Ref.USP). Therefore, studies of impurities are one of the most important works in the development of APIs and drug products.

We will understand the below details under this article;

· Definition

of Impurities

· Classification

of Impurities

· Regulatory Requirements

· Risk assessments & Control strategies

|

| Impurities in Drug Substance and Control Strategies |

Definition of Impurities

In the Pharmaceutical manufacturing, impurities can be defined as “component that is not the desired chemical entity” expected as Drug substance. These can be sourced by Starting material, raw material, Intermediate or during manufacturing operation of drug substance resulting by-product.

As per ICH (International council for Harmonization of Technical Requirements):

ICH has published a specific guidance document on “Impurities” as ICHQ3, wherein it is defined that “Any component of the new drug substance that is not the chemical entity defined as the new drug substance”.

As per WHO (World Health Organization):

“Any component present in the drug substance or drug product that is not the desired product, a product-related substance, or excipient including buffer components. An impurity may be either process- or product-related.” (ref.: WHOTechnical Report Series No. 987)

Classification of Impurities

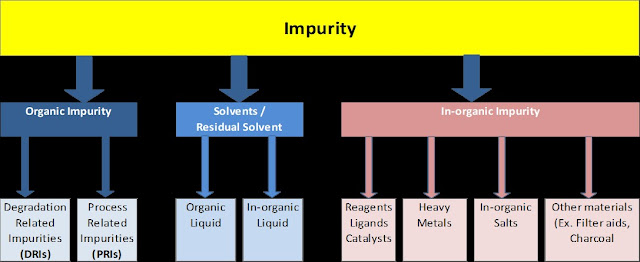

Based on the Nature and Origin of the impurities, it can be classified under following categories;

· Organic

Impurities

· In-organic impurities

· Residual Solvents

As per ICH Q3 source of the organic impurities can be the material used for the Drug substance manufacturing like Starting material, reagents, ligands, catalysts, intermediates, and can be a degradation product of the desired chemical entity / drug substance.

As we are discussing the Organic impurity, two terms i.e. PRIs (Process related impurities) & DRIs (Degradation related impurities) are very important, this classification helps us to develop the control strategy in terms of Analytical method establishment and process improvement.

On other hand, Source of In-organic impurities can be Heavy metals or other residual metals Inorganic salts, other materials (e.g., filter aids, charcoal), reagents, ligands and catalysts.

Solvents are the liquid media used for the preparation of solution / suspension during drug substance manufacturing process, these can be Organic or In-organic.

These are the general classification of impurities based on the chemistry aspect. Can be understand better with below;

Further in current scenario, impurities are also classified in other categories (based on their structure-activity relationship) and being evaluated, monitored and controlled at various steps/stages of drug substance synthesis / manufacturing. Some of these are;

· Elemental

impurities

· Nitrosamine impurities

· Genotoxic

impurities

· Mutagenic

impurities

· Azide

impurities

· Carcinogenic

impurities etc.

Regulatory Requirements

Various guidance documents are made available by Regulatoryagencies worldwide, for evaluation and control of impurities in drug substance as mentioned above. To meet the regulatory requirements on this it is very important to classify the impurity along with the source identification.

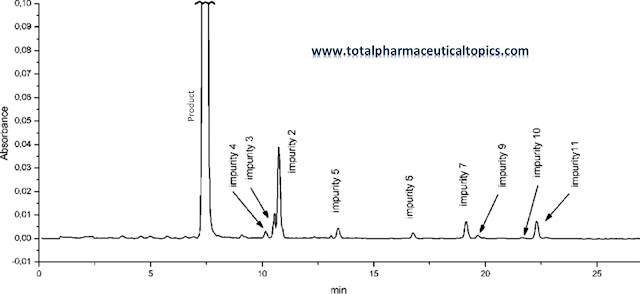

Basic requirement of regulators to perform Impurity determination with the sound scientific / technical rational, knowledge and study. Guidedby FDA as well for the ANDA sponsors. It is expected by the regulatory agencies that actual and potential impurities most likely to arise during the synthesis, purification, and storage of the new drug substance (leads DRIs) is studies and control strategy is planned.

Sound scientific appraisal is expected, in terms of study of the chemical reactions and storage conditions. Laboratory studies can be the pivot of that, to detect impurities in the new drug substance based on knowledge of the chemical reactions and conditions involved within.

Regulatory requirements

Detection

and Quantification of impurities need to be established with the appropriate

analytical methods developed based on the validation studies i.e. Analytical

Method development and validation. (ref. ICHQ2 and ICHQ14).

After Detection, Quantification of impurities and development of respective suitable analytical method; Listing of Impurities in Specifications are also expected. That can be established with the details of the analytical results obtained during the Stability studies, chemical development studies, and routine batch analysis.

At last, these identified /un-identified, specified/un-specified impurities should be qualified with the rationale for establishing impurity acceptance criteria that includes safety considerations as applicable.

Risk assessments & Control strategies

Conducting a thorough risk assessment is crucial to identify potential impurities and their associated risks early in the drug development process. This helps in implementing appropriate control strategies.

Control strategies for impurities involve a combination of techniques including selecting high-quality raw materials, optimizing manufacturing processes, employing appropriate analytical methods for detection and quantification, and implementing effective purification techniques.

As said by the requirements of ICH Q3A(R2), all types of impurities present in API at a level greater than (>) the identification threshold must conduct studies to characterize their structures, no matter they are shown in any batch manufactured by the proposed commercial process or any degradation product observed in stability studies under recommended storage conditions.

In Brief

In the pharmaceutical manufacturing impurities and management of impurities must be exercised and executed in strict compliance with the regulatory requirements due to their quality and safety concerns. Here we tried to summarize the basic understanding about the Impurities in pharmaceutical drug substance manufacturing and control strategy.

Keep Learning…..

New Chemical Entities (NCEs) in Pharmaceutical Drug Development

Clinical Trials: A Key to Pharmaceutical Development / Advancement

What is Marketing Authorization in Pharmaceutical Industry?

Research and Development: Definition

What is the difference between clinical trial & clinical research?

Drug Substance in Pharmaceuticals!! Unveiling Its Vital Role

0 Comments

If you have any doubts, Please contact us