In the series of articles on Pharmaceutical Purified water system for manufacturing of Drug substance / Drug products, previously we had information on other sections/part of the Purified water generation system i.e. Gramicid, Sand Filtration, Water Softner, Micro Filtration and Reverse Osmosis.

Another one of the important component of purified water system i.e. ELECTRO DEIONIZATION UNIT (EDI) we will have a brief introduction, requirement, benefit and more details.

What is ELECTRO DEIONIZATION UNIT (EDI)?

EDI is one of the major and important water treatment unit of Pharmaceutical purified water generation system. As the name indicates it’s a deionization process, which is an effective method for removing unwanted ions from water supply.

An EDI system is used to get water with the enhanced quality, having resistivity / Conductivity Less than or equal to 1.3 µs/cm. Conductivity is one of the major test parameter to comply before usage in the manufacturing of Drug substance.

What is resistivity / Conductivity?

A characteristic property of each material, resistivity is useful in comparing various materials on the basis of their ability to conduct electric currents. High resistivity designates poor conductors.

|

Conductivity specification as per various regulatory requirements. |

|

|

<1.3 µS/cm2 @ 25°C |

|

|

<4.3 µS/cm2 @ 20°C |

|

|

As Per WHO |

<1.3 µS/cm2 @ 25°C |

What Principle works behind the EDI system?

De-ionization works as working principle for the EDI process. Electro de-ionization is the process of water treatment for purification, to De-ionization the water, which utilizes the electricity to remove the ions from the water to reduce the Conductivity of water.

Components of EDI?

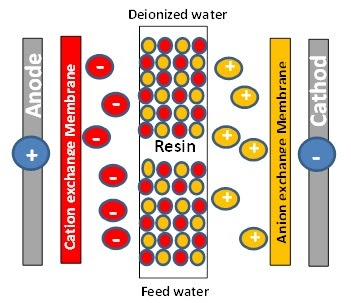

The EDI module consists of a set of chambers filled with ion exchange resins and separated by ion-exchange membranes, so that components are;

- A set of chambers filled with ion exchange resins

- Ion-exchange membranes, separates the set of chambers.

- A series of anion, cation and mixed bed resin compartments that (well known in the industrial water purification industry) is an ideal arrangement

How EDI system works?

Water enters to the system, where an applied electrical field at right-angles to the flow forces ions to move through the resins and across the membranes.

The EDI module acts, in effect, as an ion exchange bed which is continuously regenerated electrically.

When the ions are moved through the resins and between the cation or anion selective membranes, they are exchanged for H+ and OH- ions.

Ions that become bound to the ion exchange resins eventually migrate to a separate chamber under the influence of the externally applied electric field; this also produces the H+ and OH- ions necessary to maintain the resins in their regenerated state. Ions in the separate chamber are flushed to waste.

The limitations of EDI differ from conventional ion exchange. In the conventional ion exchange product water ionic purity is essentially limited by the total number of ions taken up by the resins.

EDI is limited by the maximum rate of arrival of ions. Too high an ionic load will tend to overload the module. EDI is, therefore, often used after reverse osmosis and, if the water is very hard, with degassing to remove carbon dioxide.

Benefits and Advantage of EDI?

- The unique internal design and process features a series of anion, cation and mixed bed resin compartments that (well known in the industrial water purification industry) is an optimum arrangement to produce ultrapure water.

- Due to the intrinsic nature of an EDI device, resins are continuously regenerated by the current and are never exhausted.

- The benefit is the absence of the adverse effects given by exhaustion of a resin bed, such as silicon, boron or organic breakthrough. Water purity is always consistent and maintained.

- The ion exchange beds in the EDI systems are regenerated continuously so that they do not exhaust in the same way as ion exchange beds that are operated in batch mode.

- As the impurities are removed via the concentrates, they do not build-up and exhaust the resin.

- An EDI unit may operate for many years before a replacement is required.

Caution to be taken before EDI Process.

- Carbon Dioxide will freely pass through an RO membrane, dissociating and raising the conductivity of water. Any ionic species formed from the carbon dioxide gas will lower the outlet resistivity of the water produced by EDI.

- The management of CO2 in water is typically handled in one or two ways: the pH of the water can be adjusted to allow the RO membrane to reject the ionic species or the carbon dioxied can be removed from the water using a strip gas.

0 Comments

If you have any doubts, Please contact us