Reverse Osmosis;

In continuation to series of articles on Pharmaceutical Purified Water system, here we will discuss and have basic knowledge on one of the important Component of Pharmaceutical Purified Water generation system for manufacturing of Drug substance and drug products.

Reverse Osmosis (RO) is one of the efficient system / component for the generation of pharmaceutical purified water / Process water this is being frequently employed in pharmaceutical Industry to get the desired quality / Processed water to achieve the acceptance criteria established by Various Regulatory bodies.

Let’s have Few Q’s and A’s on Reverse osmosis…………

What is Reverse Osmosis?

If we discuss the entire Pharmaceutical Process water generation system Reverse Osmosis (RO) Unit is one of the major and important component, which Works on the Principle of Reverse Osmosis process.

“As the name indicates…, it is a reverse process of osmosis. In Normal Osmosis process solvent moves from higher concentration to lower concentration”

In Reverse Osmosis a substantial pressure difference is created among the semipermeable membrane to force the solvent to move from lower concentration to higher concentration side.

What Type of membrane used in Reverse Osmosis (RO) system/Unit?

Semipermeable membrane is the part of the RO Unit to filter the Feed water to remove contaminants from the feed water. The RO membranes are the heart of the RO unit.

This Semipermeable membrane is made up of “Cellulose Acetate” this membrane has the capability of removing up to 99%+ of the dissolved salts (ions), particles, colloids, organics, bacteria and pyrogens from the feed water. This membrane has pore size of 0.01 micron to 0.0001 micron.

What is significance of Reverse Osmosis (RO) system in purified water generation system?

This filtration method being applied for the generation of Purified water and removes contaminants from the feed water with the help of semipermeable membrane.

RO filtration process is very much signified operation in purified water generation system, as this filtration operation has the capability of removing up to 99%+ of the dissolved salts (ions), particles, colloids, organics, bacteria and pyrogens from the feed water.

As compare to normal carbon filtration process it is more efficient as carbon filtration can removes the articles as small as 1 micron, whereas RO unit has the capability to remove the articles ranges from 0.01 micron to 0.0001 micron.

- Total dissolved solids reduction: Reverse osmosis is one of the rare water treatment processes that can boast a total dissolved solids reduction. The few other treatment methods with this capability are often less efficient than reverse osmosis.

- Cost-effectiveness: Reverse osmosis is popular in industrial usage because it is very economical compared with alternative filtration methods. It allows plants to treat large volumes of water while remaining comfortably within their established budgets.

- Eco-friendliness: Compared with other treatment methods, reverse osmosis is also relatively environmentally friendly. It uses less energy than other methods like thermal distillation because it does not rely on energy generation.

- Alkalinity and hardness removal: Reverse osmosis removes the calcium and magnesium ions that contribute to hard water, as well as the carbonate ions that contribute to unwanted alkalinity.

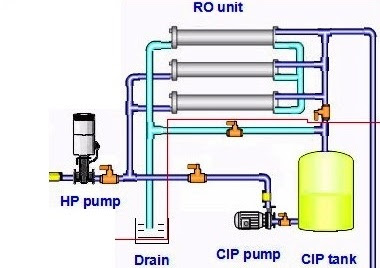

What are the key components of the RO Unit?

Major Key components of RO Unit are;

- Water Pump: The reverse

osmosis process requires a force to pass the water through the membrane known

as driving force. This force is applied in the form of pressure with the

help of pumps.

- Semipermeable Membrane Unit: This Semipermeable membrane is made up of “Cellulose Acetate” this membrane has the capability of removing up to 99%+ of the dissolved salts (ions), particles, colloids, organics, bacteria and pyrogens from the feed water. This membrane has pore size of 0.01 micron to 0.0001 micron.

People Also Read:

- Pharmaceutical Purified water system: What is Operational Flow ??

- FAQs on Pharmaceutical Purified Water system components : Gramicid

- FAQs on Pharmaceutical Purified Water system components :what is Multi Grade Filter (MGF)?

- FAQs, What is Water softener? Pharmaceutical Purified Water System components

- FAQs, What is Filtration? Pharmaceutical Purified Water System components

- What is Dosing? in Pharmaceutical Purified water system

1 Comments

Nice content 👍

ReplyDeleteIf you have any doubts, Please contact us